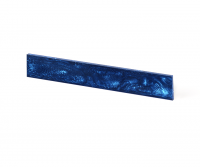

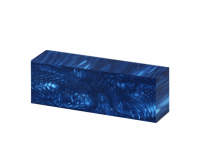

Juma slabs

colour: ivory

JUMA is a high grade, modern raw material for the manufacture of components and works of art. JUMA consists of a mixture of different mineral base materials compounded with a resin component.

The essential characteristics of JUMA are:

- excellent mechanical machinability i.e. for drilling, milling, grinding and polishing,

- minimum breakage risk due to high coefficient of elasticity and high elongation,

- high-quality surface due to high surface hardness and minimal abrasion losses,

- resistant to all conventional substances such as cleaning agents, oils, greases, weak / medium acids and bases,

- very low water absorption (hydrolysis resistant). - possibility of thermal moulding in boiling water,

- can be polished or lacquer coated to manufacture polished or matt surfaces,

- pleasant to the touch due to good thermal properties.

Applications of Juma® are:

- Knife making (here knife handles)

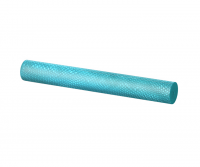

- Turning material e.g. as a pen blank for pen manufacture

- Jewelry manufacturing and design

- Restoration of furniture, art and cultural antiques with ivory inlay

- Billiard cue manufacturing, used as ferrule and for inlays

- Musical instrument construction as decorative rings, mouthpieces, piano keys, guitar bridges, and many more

- Ornamental rings and mouthpieces on tobacco pipes

- Eyeglasses manufacturing

- And many more...

We recommend a final finish / polish using buffing wheels and rubbing compound Mirka Polarshine 35 (MP35K) followed by rubbing compound Mirka Polarshine 10 (MPT10K). For extra shiny end finish use Mirka Polarshine Liquid nano Wax (MPWG1).

More information is also provided in the JUMA product description.

- Do you have any questions concerning this product?

- Further products by Bachmann Kunststoff Technologien GmbH

Great product

Polishes very nicely to a lovely creamy ivory colour with some texture to it (nowhere near supertusk or the other elforyns) giving it some more "life" and interest.

Very easy to work. But do remember proper ppe, the dust gets everywhere.

Only negative, is the reactivity to heat. So you have to go slow on the grinder. For this particular project I was working on. I used them as tapered liners in some knifehandles. I glued the juma on stabilised wood scales that was lapped completely flat. And I you go to hot/hard on the grinder they warp like crazy. They do go back to flat when cooling down. But if you're not aware of this, you could really mess up when chasing that flatness.

As I said, you just have to be aware of this. Then it's no problem.

All in all -lovely product

medium Polishing Paste - Mirka Polarshine 10

medium Polishing Paste - Mirka Polarshine 10